Our professional chimney crews travel through the towns of West Hartford, Marlborough, Manchester, Bolton, Colchester, Tolland, East Hampton, Chesire, Southington to deliver HeatShield® Chimney Relining services and chimney liner repair to residents in Central CT.

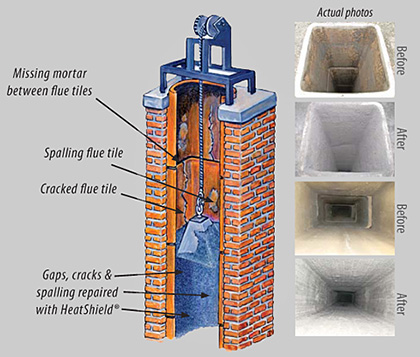

Mortar deterioration, spalling, and cracks are just a part of owning a masonry chimney. While installing a stainless steel chimney liner has been a common way to reline clay chimney liners in years past, a new innovative method has emerged thanks to CeCure Chimney Systems. HeatShield®, a specially formulated “Cerfractory®” sealant, is able to restore & revive your chimney to its optimal safety & efficiency level. The Joint Repair service & Resurfacing System using HeatShield® reconditions your chimney liner so that it works effectively and efficiently to properly vent the hazardous smoke & combustible byproducts from your fireplace out of your home.

Mortar deterioration, spalling, and cracks are just a part of owning a masonry chimney. While installing a stainless steel chimney liner has been a common way to reline clay chimney liners in years past, a new innovative method has emerged thanks to CeCure Chimney Systems. HeatShield®, a specially formulated “Cerfractory®” sealant, is able to restore & revive your chimney to its optimal safety & efficiency level. The Joint Repair service & Resurfacing System using HeatShield® reconditions your chimney liner so that it works effectively and efficiently to properly vent the hazardous smoke & combustible byproducts from your fireplace out of your home.

If your annual inspection reveals that your chimney liner is showing signs of deteriorated mortar joints, cracks, or spalling, it’s time to take immediate action. While these common chimney issues may seem small, they can begin a process that will quickly erode your chimney components and potentially pose a threat to the safety and health of your family. Our qualified chimney technicians will provide a video inspection before each HeatShield® Chimney Relining service to determine the extent of deterioration and wear & tear.

Depending on the amount of damage uncovered through the video scan, one of two HeatShield® services may be recommended. HeatShield® Joint Repair and the HeatShield® Resurfacing System are both economical alternatives to metal liner installation and chimney rebuilding. We are proud to offer these two leading-edge chimney relining methods as a cost effective way to restore your worn out chimney flue.

HeatShield® Joint Repair

The Joint Repair service is recommended for chimneys that only require repair for defective or deteriorating mortar joints. If no cracks or spalling are present in your clay liner, a simple joint repair may be all that is necessary. A foam head system customized to fit the opening of your chimney is used for both the Joint Repair service and the Resurfacing System. In this process, the foam blade and applicator tool are lowered down into the flue of your chimney a positioned directly beneath each joint.

Once in place, the HeatShield® sealant mixture is added and the applicator tool is used to push the sealant into the cracks and gaps of the mortar joint. The foam blade is then pulled upwards to smooth out the joint, making it a seamless surface. This process is repeated at each open mortar joint then reviewed by our chimney techs to ensure that the entire flue has been properly sealed.

HeatShield® Resurfacing System

HeatShield® Resurfacing System

For chimney liners that require more extensive repair, the Resurfacing System is a great choice. This in depth relining process restores the integrity of your chimney liner to produce a solid passageway for combustible gases and byproducts to escape out of your chimney. As long as the chimney structure is sound, the Resurfacing System, which is a special HeatShield® coating, can be used to cover cracks, spalling, and deterioration.

To begin, our qualified HeatShield® installers create foam applicator plug that is designed to fit flush against the inside of your flue. Specialized tools and brushes are used to remove any debris or buildup inside your chimney. Once clean, the plug is placed at the bottom of your flue and attached to a winch at the top of the chimney.

A special adhesive is applied to the inside of the flue called a “tie coat”. The adhesive is poured into the opening of the flue and pools on top of the foam applicator plug. The plug is pulled upwards by the winch and the adhesive is spread over the surface of the flue. After the adhesive has dried, the HeatShield® sealant is applied in the same manner. This process covers any cracks, crevices, or areas of vulnerability that can compromise the effectiveness and efficiency of the chimney.

Why Choose a HeatShield® System?

While there are other options for repair or relining a chimney, we have found that this method proves to be an economical and effective choice for most homeowners. There are plenty of reasons why we love to offer the HeatShield® Relining System, and these are just a few:

- Affordable - Homeowners may try to avoid repairing a damaged chimney because they feel that the fix would exceed their budget. While installing a metal chimney liner or rebuilding the chimney can be costly and time consuming, the HeatShield® Relining System is very economical.

- Durable - The sealant used in these services is a hybrid of ceramic and refractory materials that can withstand moisture, corrosive flue gases, and temperatures in excess of 2900°F. The refractory mortar is extremely heavy duty which means it will still function like new 2+ decades from now. In fact, the mortar surpasses both the National Fire Protection Association (NFPA) and the International Residential Code (IRC) requirements.

- Warranty - Our HeatShield® services are covered by a 20-year material warranty.

- Environmentally Friendly - The materials used in the HeatShield® System are created from recycled or naturally occurring components. Homeowners who like to use green alternatives for home improvement projects will love the benefits of the HeatShield® Relining system.

Call our qualified HeatShield® Installers today to find out more about our HeatShield® Relining services.